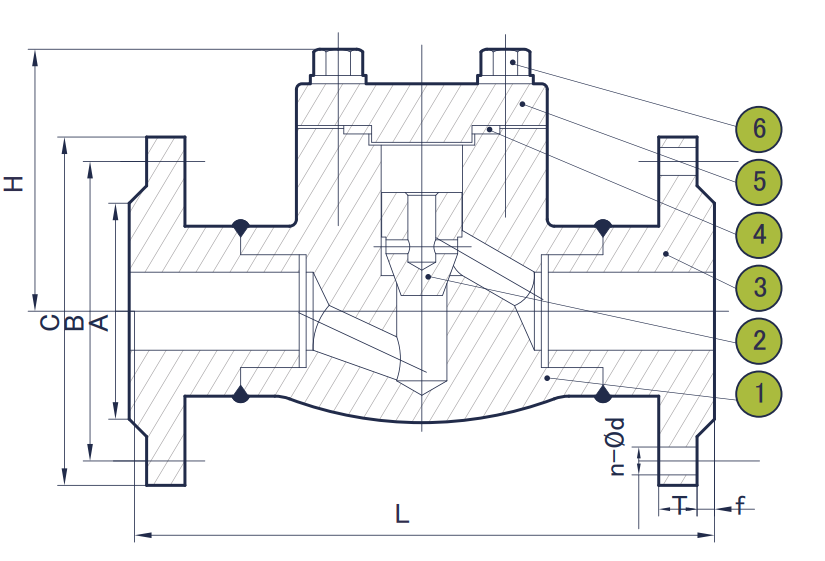

Flange Forged Steel Check Valve

Features

● Bolted Bonnet &Welded Bonnet

● Low Fugitive Emission

● Horizontal Type

● Valves with Low Cv Values

● Compact and Sturdy designs for high pressure-Temperature Service .

● A spring can be added to the lift type check valve as a piston type one.

● Swing Type Disc or Lift Type Disc

Component and Common Materials

|

No. |

Part |

Materials |

|||

|

1 |

Body |

A105 |

A182-F304 |

A182-F316 |

|

|

2 |

Disc |

13Cr |

F304+STL |

F316+STL |

|

|

3 |

Flange |

A105 |

A182-F304 |

A182-F316 |

|

|

4 |

Gasket |

SS304&Graphite |

SS304&Graphite |

||

|

5 |

Cap |

A105 |

A182-F304 |

A182-F316 |

|

|

6 |

Cap Bolt |

A193 B7 |

A193 B8 |

||

| *Enclosed is a condensed table. | |||||

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Flange Forged Steel Check Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Flange Forged Steel Check Valve |

| MOQ | 1 Pc for Flange Forged Steel Check Valve |

| Nameplate | According to customer for Flange Forged Steel Check Valve |

| Color | According to customer for Flange Forged Steel Check Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

API Trim Chart For Flange Forged Steel Check Valve

|

TRIM |

MATERIAL |

SEAT |

DISK |

BACKSEAT |

STEM |

NOTES |

|

1 |

410 | 410 | 410 | 410 | 410 | |

|

2 |

304 | 304 | 304 | 304 | 304 | |

|

3 |

F310 | 310 | 310 | 310 | 310 | |

|

4 |

Hard 410 | Hard 410 | Hard 410 | 410 | 410 | Seats 750BHN Min |

|

5 |

Hard faced | Stellite | Stellite | 410 | 410 | |

|

5A |

Hard faced | Ni-Cr | Ni-Cr | 410 | 410 | |

|

6 |

410 and Cu-Ni | Cu-Ni | 410 | 410 | 410 | |

|

7 |

410 and Hard 410 | Hard 410 | Hard 410 | 410 | 410 | Seats 750BHN Min |

|

8 |

410 and Hard Faced | Stellite | 410 | 410 | 410 | |

|

8A |

410 and Hard Faced | Ni-Cr | 410 | 410 | 410 | |

|

9 |

Monel | Monel | Monel | Monel | Monel | |

|

10 |

316 | 316 | 316 | 316 | 316 | |

|

11 |

Monel and Hard Faced | Stellite | Monel | Monel | Monel | |

|

12 |

316 and Hard Faced | Stellite | 316 | 316 | 316 | |

|

13 |

Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | |

|

14 |

Alloy 20 and Hard Faced | Stellite | Alloy 20 | Alloy 20 | Alloy 20 | |

|

15 |

304 and Hard Faced | Stellite | Stellite | 304 | 304 | |

|

16 |

316 and Hard Faced | Stellite | Stellite | 316 | 316 | |

|

17 |

347 and Hard Faced | Stellite | Stellite | 347 | 347 | |

|

18 |

Alloy 20 and Hard Faced | Stellite | Stellite |

Tips

Customers have special requirements for products and must provide the following instructions in the order contract:

1.Painting Color

2.Confirmed drawing with sign and stamp

3.Service medium, temperature and pressure range

4.Inspection standards and other requirements such as 3rd party inspection .

5.Tell requirement for the logo cast on the valve .

6.Tell requirement about the logo on the Lever. Or label sample.

7.Tell If have special requirement for package .

For almost 10 years, RXVAL has continually committed itself to offer the best Flange Forged Steel Check Valve products to meet a wide range of applications and requirements.

As an valve manufacturer, RXVAL has your perfect Flange Forged Steel Check Valve solution. Our success in the valves industry is attributed to our customer-centric team of sales personnel, engineers, workers and after-service staff that are collectively committed to providing quality products at a price you would come to expect.