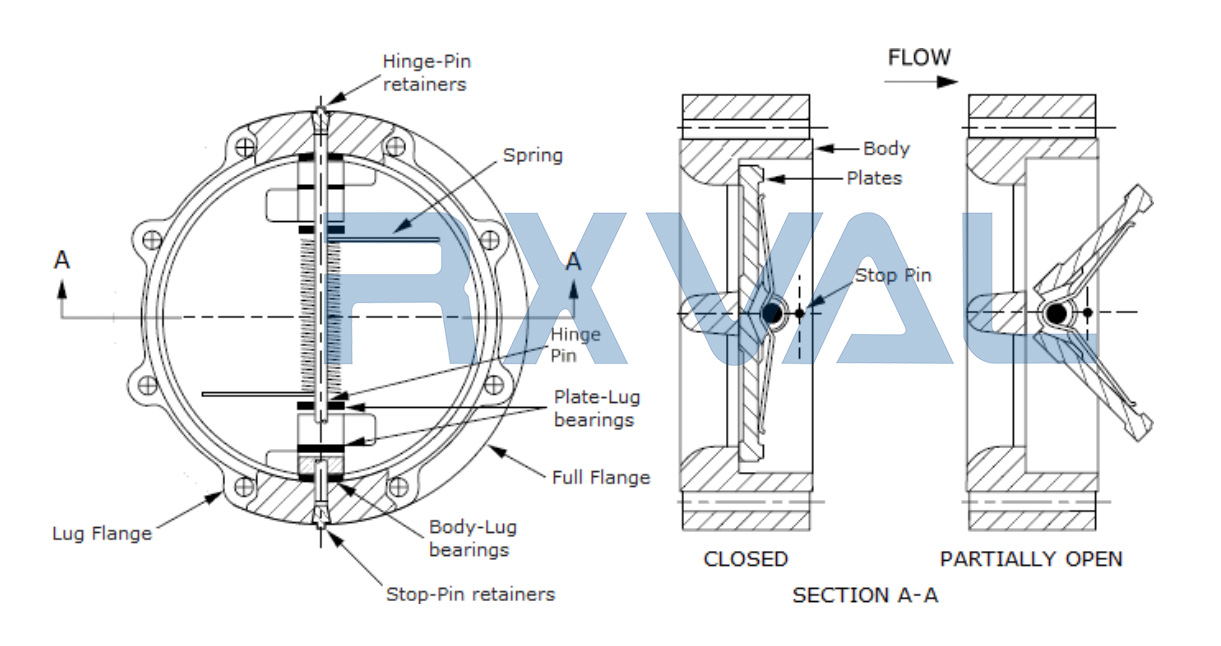

API 594 Lug Wafer Check Valve

Features

• Low Pressure Drop (High Cv)

Dual plate wafer check valves have larger open area than other designs, thus reducing pressure drop compared to swing, lift or other check valves.

• Light Weight

Reduces weight by 80–90% compared to conventional Flanged check valves.

• Lower Cost

Light weight, compact profiles and the elimination of flanges allows Dual Plate check valves to be manufactured more economically than other designs, especially as pipe diameters increase.

• Alleviates Water Hammer

RXVAL spring activated discs are designed to close our valves quickly.This assures high performance, eliminating chatter and creatingdynamic responsiveness in a non-slam design.

• Simple Installation

Easier to install, remove and replace in both new and existing piping systems.

• Retainerless Design

Ideal for critical applications where valve body penetration and the possibility of leakage cannot be tolerated.

Face to Face Dimension

|

Size |

Cl150 |

CL 300 |

CL600 |

CL900 |

CL1500 |

CL2500 |

|

2 |

60 |

60 |

60 |

70 |

70 |

70 |

|

2-1/2 |

67 |

67 |

67 |

83 |

83 |

83 |

|

3 |

73 |

73 |

73 |

83 |

83 |

86 |

|

4 |

73 |

73 |

79 |

102 |

102 |

105 |

|

6 |

98 |

98 |

136 |

159 |

159 |

159 |

|

8 |

127 |

127 |

165 |

206 |

206 |

206 |

|

10 |

146 |

146 |

213 |

241 |

248 |

254 |

|

12 |

181 |

181 |

229 |

292 |

305 |

305 |

|

14 |

184 |

222 |

273 |

356 |

356 |

|

|

16 |

191 |

232 |

305 |

384 |

384 |

|

|

18 |

203 |

264 |

362 |

451 |

468 |

|

|

20 |

219 |

292 |

368 |

451 |

533 |

|

|

24 |

222 |

318 |

438 |

495 |

559 |

|

|

30 |

305 |

368 |

505 |

|

|

|

|

36 |

368 |

483 |

635 |

|

|

|

|

42 |

432 |

568 |

701 |

|

|

|

|

48 |

524 |

629 |

|

|

|

Advantage

The main purpose of the DUAL PLATE WAFER CHECK valve is to perform the work of almost any conventional valve.

However, being smaller makes it lighter and, therefore, is more cost efficient to purchase, install and maintain.

It is also a silent check valve; because of it’s innovative design, it does not slam upon closing.

The DUAL PLATE WAFER CHECK plate design and flat seat offer many advantages.

The flat seat eliminates any possibility of board snaps in the seat, which snaps occur frequently in other valves.

When suspended in a vertical pin, the two plates have a reduced weight which eliminates excessive wear on the plate lugs.

This wear can cause the plate to collapse on the seat’s open surface, causing the valve to subsequently fail.

An important feature of the DUAL PLATE WAFER CHECK valve is that it does not depend on the pressure or flow to center the plates in relation to the sealing surface in order to make the seal.

Single plate conventional designs, even those having centering guides, require a backpressure and backflow to center the plate to the seat in order to get a non leakage adjustment. This feature becomes extremely risky in the event of reduced flow and the handling of gases at low pressure

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Lug Dual Plate Check Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Lug Dual Plate Check Valve |

| MOQ | 1 Pc for Lug Dual Plate Check Valve |

| Nameplate | According to customer for Lug Dual Plate Check Valve |

| Color | According to customer for Lug Dual Plate Check Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Tips

Customers have special requirements for products and must provide the following instructions in the order contract:

1.Painting Color

2.Confirmed drawing with sign and stamp

3.Service medium, temperature and pressure range

4.Inspection standards and other requirements such as 3rd party inspection .

5.Tell requirement for the logo cast on the valve .

6.Tell requirement about the logo on the Lever. Or label sample.

7.Tell If have special requirement for package .