API/BS1868 Swing Check Valve Flanged End

Features

● Bolted Bonnet and Pressure Seal

● Welding Seat Ring or Renewable seat rings

● Swing Type

How Does A Swing Check Valve Work

Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow.

The fluid’s pressure opens the disc to allow the water or gas through.

After the flow stops, the disc swings back into its closed position, resting against the valve’s seat and preventing backflow.

The pressure of any back-flow also serves to close the disc.

Advantages

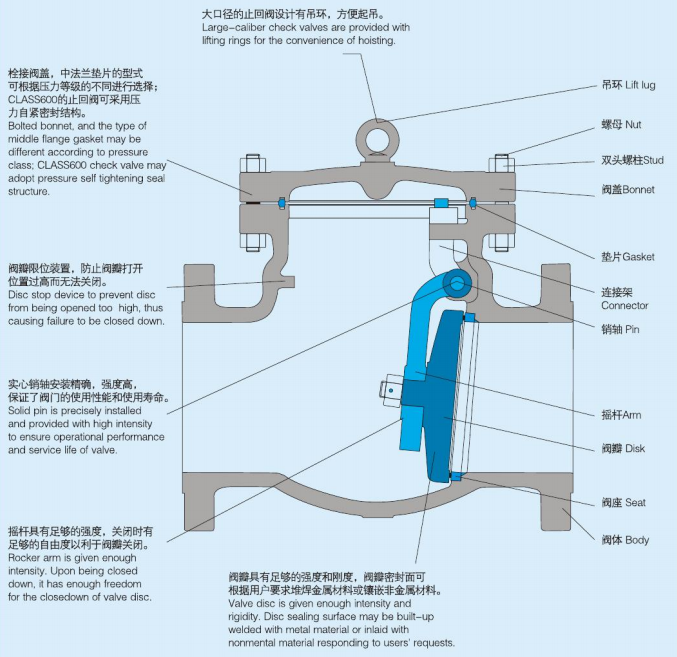

1.Bolted Bonnet,and the type of middle flange gasket may be different according to pressure class.

2.Disc Stop device to prevent disc from being opened too high,thus causing failure to be closed down .

3.Solid Pin is precisely installed and provided with high intensity to ensure operational performance and service life of valves .

4.Rocker arm is given enough intensity ,Upon being closed down ,It has enough freedom for the close down of valves Disc.

5.Valve disc is given enough intensity and rigidity,Disc sealing surface maybe built-up welded with hard material or inlaid with non-metal material responding to users’ requests .

6.Large Size Swing Check Valve are provided with Lifting Rings for Hoisting .

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Swing Check Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Swing Check Valve |

| MOQ | 1 Pc for Swing Check Valve |

| Nameplate | According to customer for Swing Check Valve |

| Color | According to customer for Swing Check Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Swing Check valves yield minimal restriction to low velocity environments and are ideal for preventing pipeline back flow in unidirectional flow applications in horizontal flow piping.

Note: Please consult RXVAL Engineering Department for upward (vertical) flow applications