Threaded Swing Check Valve 200 PSI

Features

● Full Bore

● Inside Screw and Screwed Cap

● Replaceable Seat

● Temperature range: -60 to 450 °F

Standard Material Specification

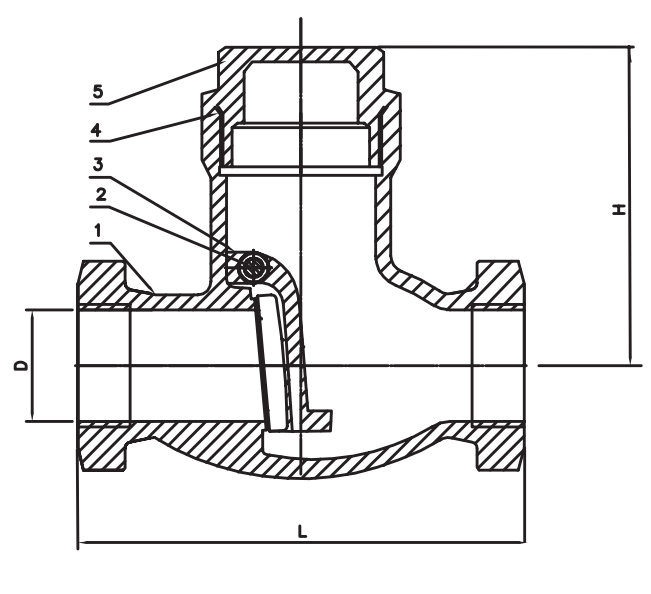

| No. | PART NAME | MATERIAL |

| 1 | BODY | CF8/CF8M |

| 2 | PIN | SS 304 |

| 3 | DISC | SS 304 / SS 316 |

| 4 | SEALING GASKET | PTFE |

| 5 | CAP | CF8/CF8M |

Dimensions and Weight

|

SIZE |

DN |

L |

H |

|

1/2” |

15 |

63 |

44 |

|

3/4” |

20 |

72 |

47 |

|

1” |

25 |

85 |

52 |

|

1-1/4” |

32 |

98 |

58.5 |

|

1-1/2” |

40 |

111 |

65 |

|

2” |

50 |

130 |

72.5 |

How Does A Swing Check Valve Work

Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow.

The fluid’s pressure opens the disc to allow the water or gas through.

After the flow stops, the disc swings back into its closed position, resting against the valve’s seat and preventing backflow.

The pressure of any back-flow also serves to close the disc.

Advantages

1.Made of investment casting for the body of Threaded Swing Check Valve

2.Factory supplied with competitive price

3.All the test reports offered before shipment for approved

4.100% testing before shipment

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Threaded Swing Check Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Threaded Swing Check Valve |

| MOQ | 1 Pc for Threaded Swing Check Valve |

| Nameplate | According to customer for Threaded Swing Check Valve |

| Color | According to customer for Threaded Swing Check Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Tips

Customers have special requirements for products and must provide the following instructions in the order contract:

1.Painting Color

2.Confirmed drawing with sign and stamp

3.Service medium, temperature and pressure range

4.Inspection standards and other requirements such as 3rd party inspection .

5.Tell requirement for the logo cast on the valve .

6.Tell requirement about the logo on the Lever. Or label sample.

7.Tell If have special requirement for package .