Horizontal Swing Check Valves

Features

●Bolted Bonnet and Pressure Seal

●Welding Seat Ring or Renewable seat rings

●Swing Type

How Does A Swing Check Valve Work

Swing check valves are among the most common types of check valves and are frequently used to manage a high horizontal flow.

The fluid’s pressure opens the disc to allow the water or gas through.

After the flow stops, the disc swings back into its closed position, resting against the valve’s seat and preventing backflow.

The pressure of any back-flow also serves to close the disc.

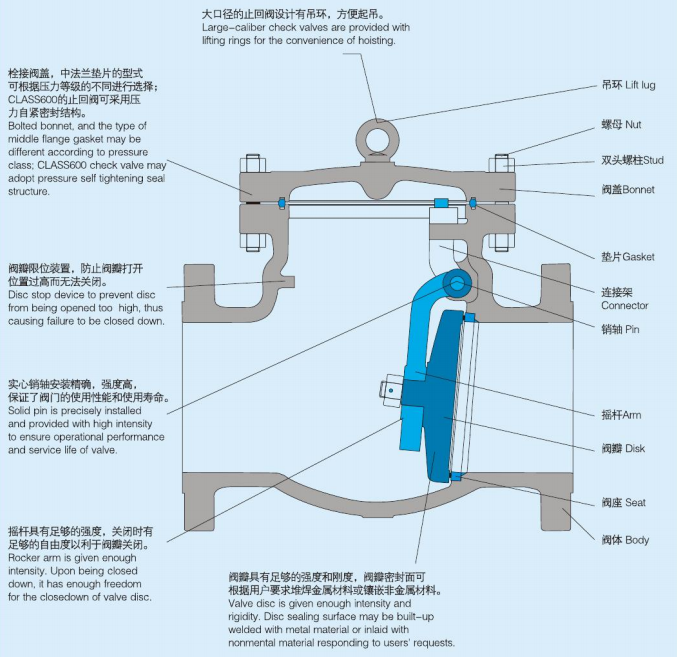

1. Body: RXVAL cast steel bodies provide low resistance flow and optimum strength and performance.

2. Cover: The cover allows access to internal components.

3. Cover Gasket: The cover gasket creates a leak-proof seal between the bonnet and body.

4. Seat Ring: To ensure a stable shutoff, the seat ring is aligned and seal-welded into the valve, then precision ground for optimal seating.

5. Disc: The disc allows uni-directional flow and restricts back flow with trouble free shutoff.

6. Swing Arm: The swing arm allows the disc to open and close.

7. & 8. Disc Nut & Pin: The disc nut and pin secures the disc to the swing arm.

9. Hinge Pin: The hinge pin provides a stable mechanism for the swing arm to operate.

10. Plug: The plug secures the arm pin inside the valve.

11. Plug Gasket: The plug gasket creates a leak-proof seal between the plug and body.

12. & 13. Cover Studs & Nuts: The cover studs and nuts secure the bonnet to the body.

14. Eyebolt: The eyebolt is use to aid in lifting the valve

Note: Classes 150 & 300 uses external hinge pin

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Swing Check Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Swing Check Valve |

| MOQ | 1 Pc for Swing Check Valve |

| Nameplate | According to customer for Swing Check Valve |

| Color | According to customer for Swing Check Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Tips

Customers have special requirements for products and must provide the following instructions in the order contract:

1.Painting Color

2.Confirmed drawing with sign and stamp

3.Service medium, temperature and pressure range

4.Inspection standards and other requirements such as 3rd party inspection .

5.Tell requirement for the logo cast on the valve .

6.Tell requirement about the logo on the Lever. Or label sample.

7.Tell If have special requirement for package .