API 6D Flange Trunnion Mounted Ball Valve

Features

●Three Piece

●Full or Reduce Bore

●High Performance Sealing Mechanism

●Fire Safety Design

●Anti-Static Spring Device

●Blow-out proof stem

●Low Emission Design

●Double Block and Bleed function

●Locking Device for Lever Operation

●Low Operation Torque

●Self-relief of Excessive Cavity Pressure

Material Specification

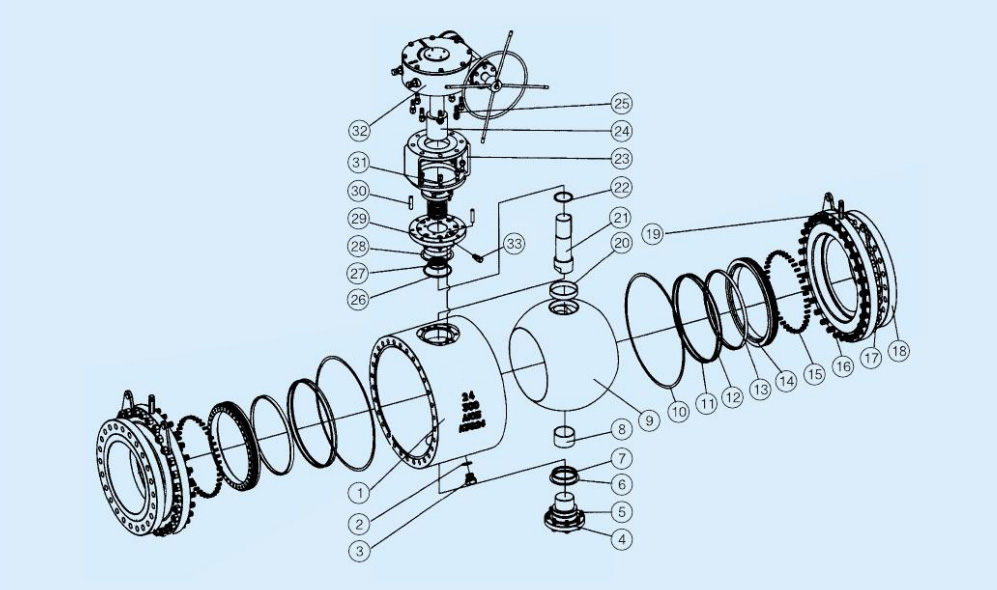

| No. | Name | Material | No. | Name | Material |

| 1 | Body | A105/F304/LF2 | 18 | Cap | A105/F304/LF2 |

| 2 | Gasket | Graphite+SS | 19 | Grease Valve | A105/F304/LF2 |

| 3 | Drain valve | A105/F304/LF2 | 20 | Bushing | PTFE+CS/PTFE+SS |

| 4 | Bottom Cover | A105/F304/LF2 | 21 | Stem | A182 F6a/F304 |

| 5 | Bolt | A193 B7/B8/L7 | 22 | Bushing | PTFE+CS/PTFE+SS |

| 6 | Gasket | Graphite+SS | 23 | Yoke | A216 WCB |

| 7 | O-Ring | Viton | 24 | Sleeve | ANSI 1025 |

| 8 | Bushing | PTFE+SS | 25 | Bolt | A193 B7 |

| 9 | Ball | A105+ENP/F304 | 26 | O-Ring | Viton |

| 10 | Gasket | Graphite+SS | 27 | O-Ring | Viton |

| 11 | O-Ring | Viton | 28 | Gasket | Graphite+SS |

| 12 | Fire Ring | Graphite | 29 | Bonnet | A105/F304/LF2 |

| 13 | Seat Sealing | PTFE,PEEK,NYLON | 30 | Pin | A182 F6a |

| 14 | Seat | A105+ENP/F304 | 31 | Bolt | A193 B7 |

| 15 | Spring | Inconel 600 | 32 | Gear | / |

| 16 | Bolt | A193 B7/B8/L7 | 33 | Grease Valve | A105/F304/LF2 |

| 17 | Nut | A194 2H/8/7 |

Advantages

1.Forged Body

2.Pressure relief valve to avoid cavity over pressure when applicable

3.Emergency built-in stem and seat sealant injection system

4.DBB design enables the use of a single valve with two independently functioning seats on each end of the valve while allowing the cavity between the seating surfaces to be vented or bled.

5.Open and close quickly

6.Self-Relieving Structure

7.Fire safety and Anti-static

8.Locking Device Option

9.Corrosion Resistance

10.Extension Stem Option

Other Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for API 6D Flange Trunnion Mounted Ball Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for API 6D Flange Trunnion Mounted Ball Valve |

| MOQ | 1 Pc for API 6D Flange Trunnion Mounted Ball Valve |

| Nameplate | According to customer |

| Color | According to customer |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Pressure Testing Standard for the Ball Valve

|

CL |

150LB |

300LB |

600LB |

800LB |

900LB |

1500LB |

2500LB |

|

Shell (Mpa) |

3.0 |

7.7 |

15.4 |

21.0 |

23.0 |

37.5 |

63.9 |

|

Back Seat (Mpa) |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

|

Seat (Mpa) |

2.2 |

5.7 |

11.3 |

15.4 |

16.9 |

27.5 |

46.2 |

|

Air (Mpa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

RXVAL can manufacture the API 6D Flange Trunnion Mounted Ball Valve in accordance with ASME B16.34 and API6D. Just feel free to contact us now to get best prices. 10 years of experience. High quality. Big stock. Fast delivery.