SMS Sanitary Ball Valve with ISO5211 Mounting Pad Clamp End

Features

● Full Port for Unrestricted Flow

● 8- 12 Ra finish on all internal surfaces

● Virgin PTFE ball seats and cavity fillers

● All materials comply with FDA, USDA and 3-A requirements

● Triple PTFE Stem Seal Design, Live Loaded

● Standard Tri-Clamp ends for sanitary connections

● Actuator Ready ISO5211 Direct Mounting Pad

● Clamp end connections and three piece swing-out design for easy cleaning and maintenance.

SMS sizes

|

Size |

Outside Diameter(OD) |

|

Φ19 |

19mm |

|

Φ25 |

25.4mm |

|

Φ32 |

31.8mm |

|

Φ51 |

50.8mm |

|

Φ63 |

63.5mm |

|

Φ76 |

76.2mm |

|

Φ89 |

89mm |

|

Φ102 |

101.6mm |

|

Φ108 |

108mm |

The mechanical sealing requirements for sanitary valves:

1.Sanitary valves must be built in compliance with these mechanical sealing requirements:

2.In line with GMP requirements

3.Must have a surface fineness of 1.6 or above

4.Must be capable of in situ cleaning and in situ disinfection of the contact surface

5.Must provide a smooth flow and transition for the medium with no accumulation of materials

6.There must be a structure for preventing material-fleeing outside the sealing surface.

Advantage

1 The structure of Sanitary ball valves is simple, the weight and volume are relatively small, and it is easy to disassemble and repair.

2 Since the valve stem only rotates, the packing seal of the valve stem is not easily broken, and the sealing capacity increases as the medium pressure increases.

3 The fluid resistance is small, and the full-bore ball valve has substantially no flow resistance. Pneumatic ball valves are one of the least fluid resistances in all valve classifications.

4 The operation is simple and rapid, and it only needs to be rotated by 90° from full opening to full closing, which is convenient for long-distance control.

5 It is suitable for a wide range of applications, from a few millimeters to a few meters, from high vacuum to high pressure.

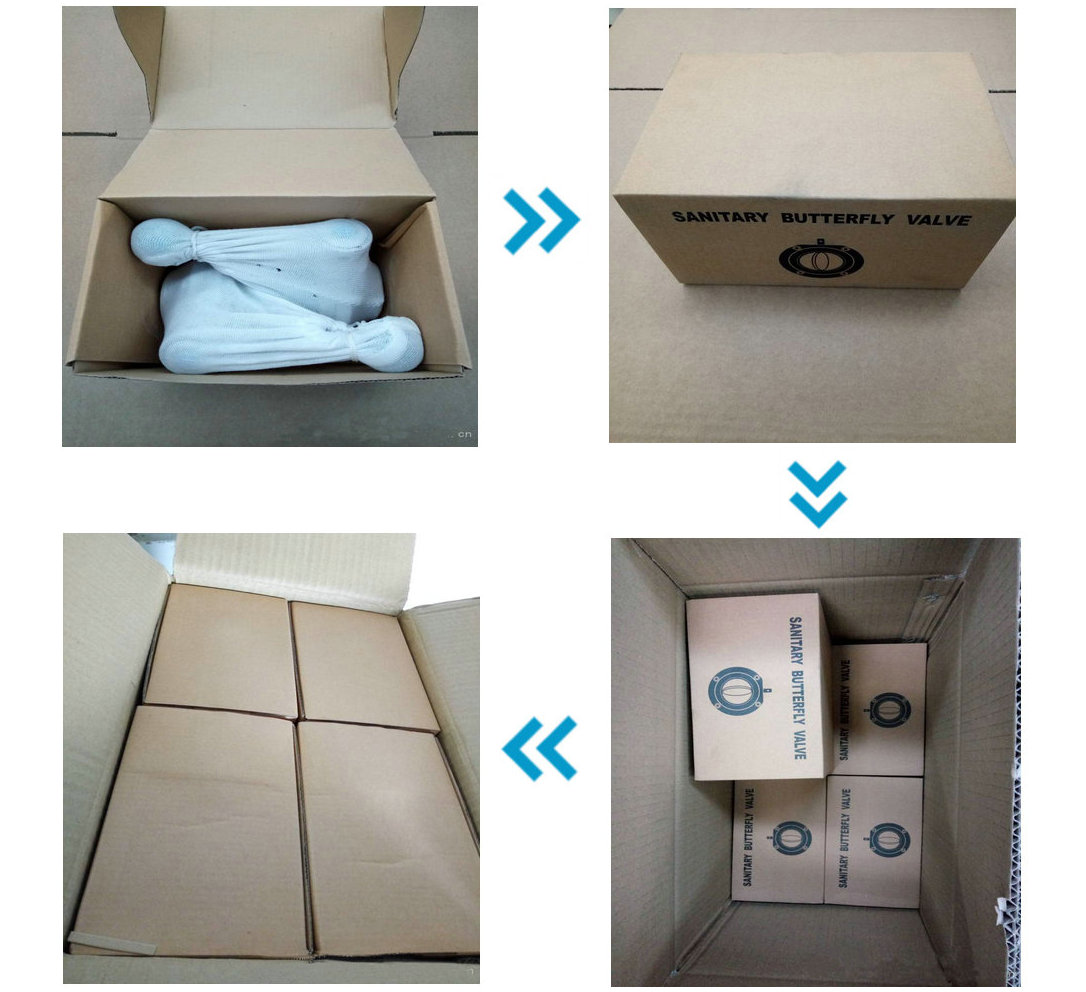

Package

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Sanitary Ball Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Sanitary Ball Valve |

| MOQ | 1 Pc for Sanitary Ball Valve |

| Nameplate | According to customer for Sanitary Ball Valve |

| Color | According to customer for Sanitary Ball Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

How to Install Sanitary Ball Valve

1.During the construction, the construction contractor, the safety department, the factory production department and the construction unit shall fully coordinate to clarify the scope of responsibility for the operation;

2.The full-time responsible person shall work on the site in the respective work responsibility area;

3.When removing or installing sanitary valves, make changes and arrangements for daily production within a certain range affected by this operation, then remove and cut off the medium in the pipe;

4.Support to fit the weight of the sanitary valve should be provided at the work site to prevent the sanitary valve from sinking and the center of the piping;

5.After the completion of the work, the company should prepare for the pressure test, air-tightness test, non-destructive inspection and other inspection items;

6.Before entering the production operation at the end of the operation, the inner cleaning of the pipe network should be carried out, the removal of the blind plate on the pipe should be confirmed, and the operated valve should be restored to the open and close state before construction.