Sanitary check Valve Thread End

What is a sanitary check valve?

Sanitary check valves are specifically used for the food handling and processing industries to prevent back-flow of product. Commonly used with liquid products, spring check valves are designed to assist closure pressure to create a positive shutoff.

Features

Sanitary check valve is designed for use in process piping installations to prevent reverse flow. It is in two parts and polished inside and out totally. This kind check valve is combined with many elastomeric combinations as well as different end types. Thread end connection allow it can be used to control medium flow and replace easily. The pressure required to open the valve and be adjust by swapping out the inner spring (only one spring included) or rotating the spring plate. All valves are designed to meet high requirement of the United States 3-A standard, Seal EPDM, Teflon PTFE meet FDA standard.

SMS sizes

|

Size |

Outside Diameter(OD) |

|

Φ19 |

19mm |

|

Φ25 |

25.4mm |

|

Φ32 |

31.8mm |

|

Φ51 |

50.8mm |

|

Φ63 |

63.5mm |

|

Φ76 |

76.2mm |

|

Φ89 |

89mm |

|

Φ102 |

101.6mm |

|

Φ108 |

108mm |

Sanitary check valves are different from many other types of valves, for ss check valves work automatically and most are not controlled by a person or any external control. Accordingly, most do not have any valve handle or stem. Thus there is an important concept in hygienic check valves, it is, the cracking pressure. Cracking pressure is the minimum upstream pressure at which the valve will operate. So the check valve is designed for and can, therefore, be specified for a specific cracking pressure.

How does Sanitary Check Valve Working

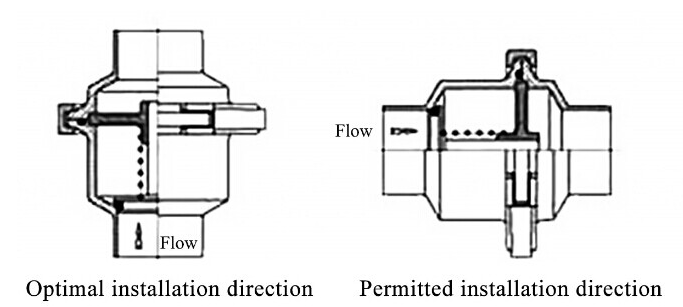

A check valve opens when the pressure below the valve plug exceeds the pressure above the valve plug and the spring force. The valve close when pressure equalization has been achieved. The below picture shows the right installation:

The structure of a Sanitary check valve is usually very simple, including parts such as a valve body, a valve seat, a valve disc, and a cover.

The working principle of the Sanitary check valve is to allow one-way flow and automatically prevent reverse flow.

This type of valve is sensitive to flow and relies on the medium to open and close the valve seat. The inner disc allows the medium to flow forward, thereby forcing the valve to open. Then the flow reverses and the valve is closed.

The Sanitary check valve is one of the few fully automated valves that can be circulated automatically without manual intervention.

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Sanitary check valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Sanitary check valve |

| MOQ | 1 Pc for Sanitary check valve |

| Nameplate | According to customer for Sanitary check valve |

| Color | According to customer for Sanitary check valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |