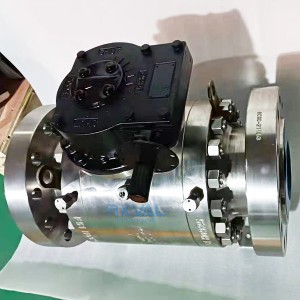

High Pressure Forged Steel Ball Valve

Features

● Fire Safety Seat Sealing

● Two-Piece or Three-Piece Forged Body

● Blowout-Proof Stem

● Anti-Static Spring Device

● 100% leakage tested

● Extended Body is for option

Advantages

1. All parts are forgings

2. Lower mounted valve stem and inverted sealing structure of equipment are adopted

3. The use of Mosaic valve seat, seat back equipment O ring, to ensure that the medium leakage

4. The sealing surface use nylon,PTFE,Delvon,PEEK or metal seat for good performance and long service life.

5. Suitable for chemical industry, petroleum, natural gas, metallurgy and other industries and hydrogen sulfide medium, impurities, corrosion severe long - term natural gas pipeline.

Standard Material Specification

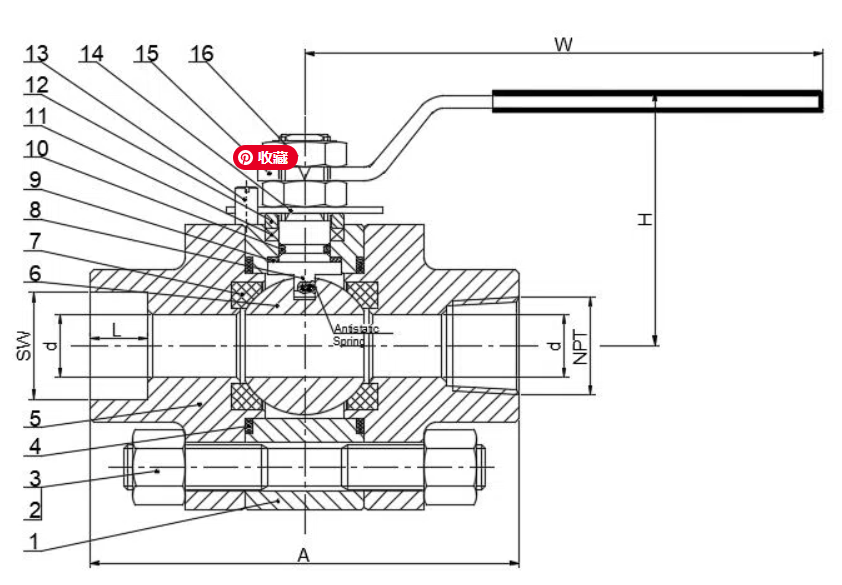

Dimensions and Weights (800LB)

|

SIZE |

d |

A |

H |

W |

|

1/2” |

14 |

92 |

62 |

130 |

|

3/4” |

19 |

111 |

73 |

160 |

|

1” |

25 |

127 |

95 |

220 |

|

1-1/4” |

31 |

140 |

100 |

250 |

|

1-1/2” |

38 |

152 |

110 |

250 |

|

2” |

49 |

178 |

120 |

300 |

Why Choose Forged Steel Ball Valve

1 The structure is simple, the weight and volume are relatively small, and it is easy to disassemble and repair.

2 Since the valve stem only rotates, the packing seal of the valve stem is not easily broken, and the sealing capacity

increases as the medium pressure increases.

3 The fluid resistance is small, and the full-bore ball valve has substantially no flow resistance. Pneumatic ball valves are one of the least fluid resistances in all valve classifications.

4 The operation is simple and rapid, and it only needs to be rotated by 90° from full opening to full closing, which is convenient for long-distance control.

5 It is suitable for a wide range of applications, from a few millimeters to a few meters, from high vacuum to high pressure.

| No. | Part | Material |

| 1 | BODY | A105/F304/F316 |

| 2 | Stud Bolts | A193 B7/B8 |

| 3 | Nut | A194 2H /8 |

| 4 | Body Gasket | Graphite + 304/316 |

| 5 | Bonnet | A105/F304/F316 |

| 6 | Ball | F304/F316 |

| 7 | Stem Ring | RPTFE |

| 8 | Stem | ASTM A276 410/304/316 |

| 9 | Thrust Washer | RPTFE |

| 10 | Stem “O”Ring | VITON |

| 11 | Packing | Graphite |

| 12 | Gland | Stainless Steel |

| 13 | Positioning Pin | Stainless Steel |

| 14 | Positioning Plate | Stainless Steel |

| 15 | Lever | SS 201 + Plastic |

| 16 | Stem Nut | A3/SS 304 |

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for Forged Steel Ball Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for Forged Steel Ball Valve |

| MOQ | 1 Pc for Forged Steel Ball Valve |

| Nameplate | According to customer for Forged Steel Ball Valve |

| Color | According to customer for Forged Steel Ball Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

Tips

Customers have special requirements for products and must provide the following instructions in the order contract:

1.Painting Color

2.Confirmed drawing with sign and stamp

3.Service medium, temperature and pressure range

4.Inspection standards and other requirements such as 3rd party inspection .

5.Tell requirement for the logo cast on the valve .

6.Tell requirement about the logo on the Lever. Or label sample.

7.Tell If have special requirement for package .