Introduction

This article contains all the information you need to know about 1000 PSI Ball Valve

Read further and learn more about:

3.Material of 1000 PSI Ball Valve

4.Parts and structure of 1000 PSI Ball Valve

5.End Connection of 1000 PSI Ball Valve

6.What is the operation of 1000 PSI Ball Valve ?

7.How does 1000 PSI Ball Valve work ?

8.How to do the pressure test of 1000 PSI Ball Valve ?

9.What industry of 1000 PSI Ball Valve service for ?

1.What is ball valve?

A ball valve is a shut-off valve that allows, obstructs, and controls the flow of LIQUIDS, GASES, and STEAM in a piping system by rotating the ball having a bore inside the valve. The ball is mounted against two seats and has a shaft that connects it to the operating and control mechanism that rotates the ball. When the cross-section of the bore is perpendicular to the area of the flow, the fluid is not permitted to pass through the valve. The fluid flows through from the valve, and the fluid flow rate depends on the area of the bore exposed to the floor.

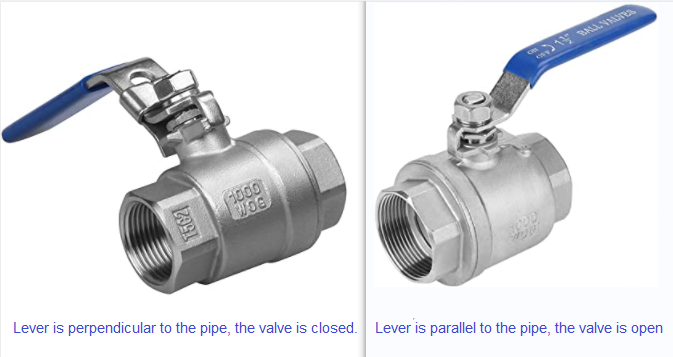

The simplest operation of a ball valve is through the use of a wrench or a lever manually turned by an operator. Torque is applied to rotate the lever arm by 90° by either clockwise or counterclockwise to open or close the valve. If the lever arm is parallel to the pipe, it indicates that the valve is open. If the lever arm is perpendicular to the pipe, it indicates that the valve is closed.

2.Type of 1000 PSI ball valve

1000 PSI Ball valves may be classified according to their housing assembly

- One-Piece Ball Valve

A one-piece ball valve has a single-piece cast body that houses the internal components of the ball valve. This eliminates the risk of leakage of the fluid from the valve. One-piece ball valves are the cheapest ball valves and always have a reduced bore.

Screwed one-piece ball valves can be cleaned, serviced, and repaired, but dismantling requires special tools.

Two-Piece Ball Valve

A two-piece ball valve consists of housing divided into two pieces that are fitted together. The main piece contains the ball and a connection to one end, and the other piece holds the internal components together and has a connection to the other end. Two-piece housing is the most common type among ball valves. The two parts can be dismantled for cleaning, maintenance, and inspection but it requires removal of the valve from the pipe.

Two-Piece Ball Valve

A three-piece ball valve consists of the housing for the internal components of the valve which are fitted and held together by bolt connections to its two ends. The ends are threaded or welded to the main pipe.

Three-piece ball valves are used for applications that rely heavily on valves, that their maintenance activities must frequently be done. They can be cleaned and serviced easily and their seats and seals can be routinely replaced by just taking the valve body out without disturbing the two ends.

3.Material of 1000 PSI Ball Valve

The most common housing materials are brass, stainless steel, The ball is usually made of chrome plated steel, chrome plated brass, stainless steel . The seats are often made of Teflon, but could also be made of other synthetic materials or metals.

Brass Ball Valve

Brass is an alloy of copper and zinc,and has good mechanical properties. Brass has the largest market share. Brass is a tough, strong, and durable metal that can withstand high temperatures and pressures.

Brass ball valves are not difficult to fabricate because of their malleability, and they are also easy to cast and weld. They are lighter and cheaper than stainless steel ball valves. They are also easy to assemble in the piping system.

Stainless Steel Ball Valve

Stainless steel is a type of steel that contains higher chromium content and some amounts of nickel. The chromium content of stainless steel makes it acquire a superior corrosion resistance. Stainless steel is known for its excellent strength, toughness, and durability. It also retains its strength in high temperatures and pressures.

Most stainless steel is austenitic. Type 304 and 316 are the most common, 316 has the best corrosion resistance.

4.Parts and structure of 1000 PSI Ball Valve

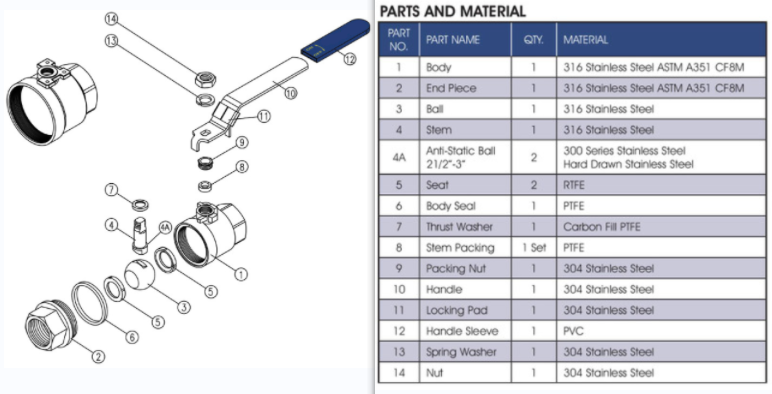

The basic components of a ball valve include the following:

Body

All internal components of a ball valve are contained inside the valve body .

Ball

The ball is a sphere that has a channel in its center. The channel is called the bore.The fluid across the valves by the bore.

A ball valve may have a solid ball or a hollow ball. A hollow ball is more lightweight and cheap compared to a solid ball.

Stem

The stem connects the ball to the control mechanism(such as lever or a hand-wheel or or operated by an electric, pneumatic,hydraulic actuation) that rotates the ball. The stem has seals such as O-rings and packing rings to seal the stem and the bonnet to avoid leakage of the fluid.

Bonnet

The bonnet is an extension of the valve body that contains and protects the shaft and its packing. It may be welded,screwed or bolted to the body. It is also made with the same material of valve body .

Seat

The valve seats provide sealing between the ball and its body. The upstream seat is adjacent to the inlet side of the valve. The downstream seat is found on the opposite side of the upstream seat which is adjacent to the discharge side of the valve.

5.End Connection of 1000 PSI Ball Valve

Threaded End

SW End

BW End

Tri-Clamp End

●Threaded

There is different kind of threaded,Such as BSPP,BSPT,NPT

BSP is a widely accepted standard for sealing pipes and fittings in most parts of the world, with the notable exception of the United States of America. The BSP consists of both female and male threaded ends for the valve and pipe. They have a flank angle of 55 degrees with rounded roots and crests (valleys and peaks).

The BSP standard has two types of thread: the parallel (straight) threads BSPP and the taper threads BSPT. The BSPP is defined by the standards ISO 228-1:2000 and ISO 228-2:1987, while the BSPT is defined by the standards ISO 7, EN 10226-1, and BS 21.

NPT is also known as the National Pipe Thread (NPT). It also has a standard for both tapered and straight thread types. The flank angle is 60 degrees with flat roots and crests. There are many types of NPT, but the two main types are the American National Standard Taper Pipe Thread (also known as NPT) and the American National Standard Straight Pipe Thread (NPS).

Metric threads are a general-purpose screw thread standard. It is a parallel type thread known by the ‘M’ designation followed by a number indicating the threads major diameter. The major diameter and the pitch size is used to characterize the thread standard. It is a V-shaped thread with a flank angle of 60 degrees. The metric thread is defined by the standard ISO 68-1.

●Welded

Welded connections are used where zero leakage is important to the system. This is typically in high-temperature and high-pressure piping systems. They are a permanent type of connection. There are two main types of welded connections for valves:

Socket welded Ball Valve

This type of welded connection has the valve diameter larger than the pipe’s diameter, such that the pipe can fit into the valve socket end. The weld is done around the rim of the valve end that is connected to the pipe.

Butt-welded Ball Valve

In this welded connection, the valve ends and the pipe ends have the same diameter. The connection ends are placed against each other and grooved to create a space for the weld. The weld is done around the rims of the connection. Butt welding is common for smaller pipe sizes.

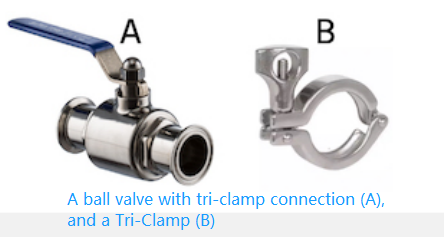

●Tri-Clamp Connection

A Tri-Clamp is a special type of flanged connection where the flanged ends of the valve (A) and pipe are held together with a hinged clamp (B) that has a gasket in between. The tightening of the clamp squeezes the pipe and the valve end ensuring a sealed connection.

6.What is the operation of 1000 PSI Ball Valve?

Ball valves can be operated by manual operation or with actuators.

Manual ball valves require an operator to turn the lever or handle on the top of the valve.

Actuator operation includes Electric-actuated ,Pneumatic actuated and Hydraulic-actuated .

Electric-actuated: Electric-actuated ball valves, also called motorized ball valves, are recommended for low-cycle applications that don’t have access to compressed air. This type of actuation offers slower index times to help prevent water hammer in high-pressure situations.

Pneumatic-actuated: If the situation can work with air, you may be able to use pneumatic-actuated ball valves (Include Singe Acting Pneumatic ball valve,and Double Acting Pneumatic ball valve ). These are primarily used for applications that require high durability and fast cycle times, and are one of the most durable choices.

Hydraulic-actuated :Hydraulic-actuated ball valves are similar to pneumatic-actuated, but can offer more torque output. Hydraulics may require additional components and are typically more expensive than other options.

Pneumatic-Actuated Ball Valve

Electric-actuated Ball Valve

Level Operated Ball Valve

7.How does 1000 PSI Ball Valve work ?

1000 PSI Ball Valves are flow control devices with hollow, perforated, rotating balls that regulate the flow of liquid through them. It is open when the ball's hole is aligned with the flow inlet. It becomes closed when the handle is rotated 90 degrees.

8.How to do the pressure test of 1000 PSI Ball Valve ?

The valve is in a half-open state, one end is introduced into the test medium, and the other end is closed. Rotate the sphere several times, and open the closed end to check when the valve is in the closed state. At the same time, check the sealing performance of the packing and gasket, and there must be no leakage. Then introduce the test medium from the other end and repeat the above test.

9.What industry of 1000 PSI Ball Valve service for

Common applications of 1000 PSI brass ball valves are in food, chemical, and oil and gas processing, and in conveying gaseous fluids. It is also safe to use in the delivery of potable drinking water.But brass can not work for Chloride solutions (e.g. seawater) or demineralized water may cause dezincification. Dezincification is a form of corrosion where which zinc is removed from the alloy. This creates a porous structure with a greatly decreased mechanical strength.

There are applications where the use of a 1000PSI stainless-steel ball valve is an excellent choice. They are used in swimming pools to handle chlorinated water. In harsh industrial environments such as desalination and petroleum refining plants, they offer better resistance to corrosive chemicals under high temperatures and pressures. In breweries, stainless steel pipes and valves are used to handle wort, a reactive liquid that is extracted during the mashing process. Three-piece 1000PSI ball valves are commonly used in the food and beverage and pharmaceutical industries where sanitation is crucial to safety and product quality.

10.What is the service life of the 1000 WOG ball valve?

Ball valves is working for the on/off control of various types of media.It must be some degree of wear and tear when working. So can we know the valve’s actual service life?

In fact there are several factors that will affect a ball valve’s service life, which is why the majority of manufacturers don’t set lifespan guarantees.

●What type of media the valve is working with?

Ball valves provide on/off control for gases and liquids, such as, water, oil, chemicals, and air. It’s best to avoid abrasive media, or media with suspended particulates. The abrasiveness of the media can result in premature valve seal failure, which can cause leaks. The valve operating torque could also rise and cause the actuator to fail.

●What is the material of the ball valve?

The medium decide the what material is chosen for ball valve.

The body and seals must be made of materials that are compatible with the temperature, pressure rating, and chemical makeup of the media flowing through the valve.

For example metal material includes stainless steel, brass, and bronze are corrosion resistant and highly durable. Metal ball valves are the recommended choice for applications with high temperatures and are the safest and best option for pressurized gases.

●What are the temperature and pressure ratings?

The valve media pressure and temperature influence the type of valve materials you should use. This is referred to as the pressure/temperature rating. As the media temperature increases in the valve, the pressure must decrease, and vice versa. These factors combined with cycle frequency affect the longevity of the ball valve.

Ball valves used in applications that are close to the defined pressure and temperature ratings can last many years if the valve is infrequently cycled. If the valve is cycled more frequently, the same valve in the same application may have a shorter lifespan or need more servicing. Ball valves that operate near the upper limits of the valve’s pressure and temperature ratings typically yield fewer cycles.

●What type of actuation ?

Ball valves can be operated by manual operation or with actuators. Manual ball valves require an operator to turn the lever or handle on the top of the valve.

Actuated ball valves are the automated option. In most applications, the actuator will long outlast the ball valve.

●What level of maintenance ?

If you’re looking to maintain your ball valves, you should select a valve designed for serviceability. 3pc ball valves are designed so that the seals and center section of the valve can be safely and quickly replaced, This design is the best choice if medium could cause extreme wear and tear. 1pc ball valve and 2pc ball valves should be replaced instead of repaired, since they are not designed to be taken apart.

With the suitable valve design and material for your application, you can ensure that your ball valves spend as much time in service as possible and that you’re getting the most value out of your investment.

11.TOP 5 Leading 1000 PSI Ball Valve Manufacturer in China

●ANIX VALVE GROUP CO.,LTD.

Location:No. 422, 22nd Road, Binhai Park, Wenzhou ,Zhejiang P.R China

Company Type : Manufacturer

Website: http://www.anixvalve.cn/

●Zhejiang Linuo fluid control Technology Co., Ltd.

Location: No.1QixinRoad, Economic Development Zone, Ruian City,Zhejiang,China

Company Type :Manufacturer

Website: https://en.linuovalve.com/

●Wenzhou Ruixin Valve Co., Ltd.

Location: No.658, 3 Street,Binhai Industry Park,Wenzhou City, Zhejiang, China

Company Type :Manufacturer

Website: https://www.rxval-valves.com/

●CNNC SUFA Technology Industry Co.,Ltd.

Location: Suzhou National Hi-Tech Industrial Development Zone, Huguan Industrial Park,Suzhou City,Jiangsu P.R,China

Company Type :Manufacturer

Website: http://en.chinasufa.com/

●China•Yuanda Valve Group Co., Ltd.

Location: Yincun Town, Longyao County, Hebei Province

Company Type :Manufacturer

Website: https://www.yuandavalves.com/

Post time: Sep-08-2022