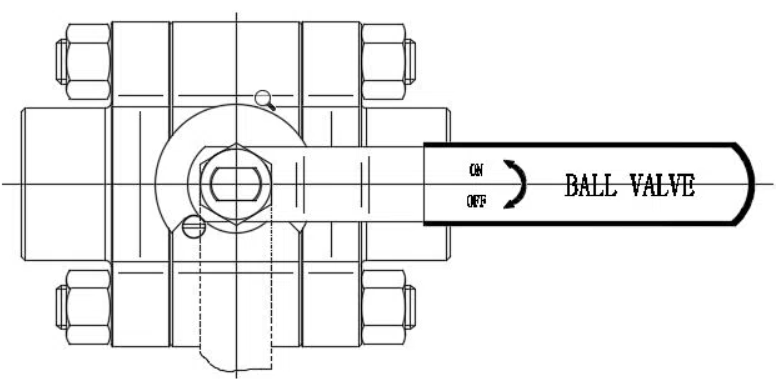

API Threaded High Pressure Ball Valve BW/SW

Features

● Fire Safety Seat Sealing

● Two-Piece or Three-Piece Forged Body

● Blowout-Proof Stem

● Anti-Static Spring Device

● 100% leakage tested

Advantages

1.All parts are forgings for high pressure.

2.Factory supplied with competitive price

3.All the test reports offered before shipment for approved

4.100% testing before shipment and ensure 0 leakage for High Pressure Ball Valve .

Standard Material Specification

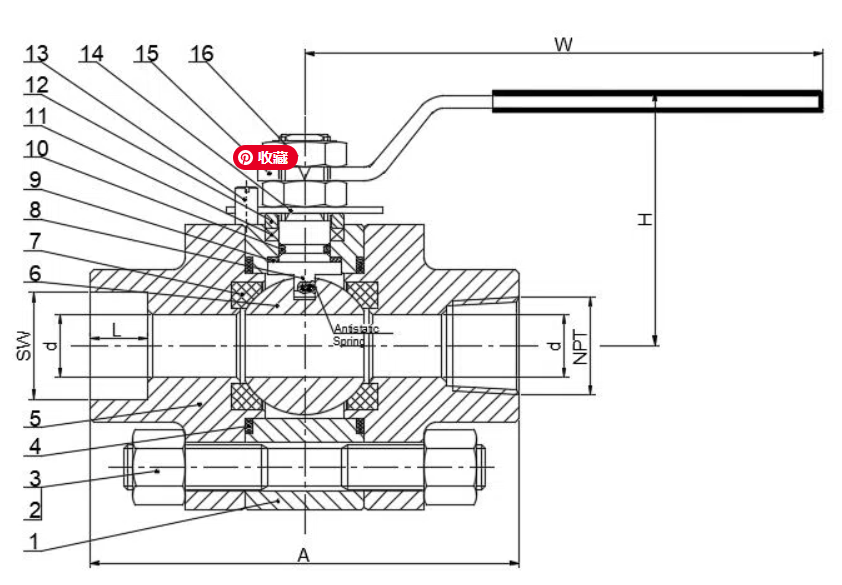

| No. | Part | Material |

| 1 | BODY | A105/F304/F316 |

| 2 | Stud Bolts | A193 B7/B8 |

| 3 | Nut | A194 2H /8 |

| 4 | Body Gasket | Graphite + 304/316 |

| 5 | Bonnet | A105/F304/F316 |

| 6 | Ball | F304/F316 |

| 7 | Stem Ring | RPTFE |

| 8 | Stem | ASTM A276 410/304/316 |

| 9 | Thrust Washer | RPTFE |

| 10 | Stem “O”Ring | VITON |

| 11 | Packing | Graphite |

| 12 | Gland | Stainless Steel |

| 13 | Positioning Pin | Stainless Steel |

| 14 | Positioning Plate | Stainless Steel |

| 15 | Lever | SS 201 + Plastic |

| 16 | Stem Nut | A3/SS 304 |

Dimensions and Weights (800LB)

|

SIZE |

d |

A |

H |

W |

|

1/2” |

14 |

92 |

62 |

130 |

|

3/4” |

19 |

111 |

73 |

160 |

|

1” |

25 |

127 |

95 |

220 |

|

1-1/4” |

31 |

140 |

100 |

250 |

|

1-1/2” |

38 |

152 |

110 |

250 |

|

2” |

49 |

178 |

120 |

300 |

At its most basic level, forging is the process of forming and shaping metals through the use of hammering, pressing or rolling. The process begins with starting stock, usually a cast ingot (or a "cogged" billet which has already been forged from a cast ingot), which is heated to its plastic deformation temperature, then upset or "kneaded" between dies to the desired shape and size.So that Forged Steel Ball Valve have a better performance.

More Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for High Pressure Ball Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for High Pressure Ball Valve |

| MOQ | 1 Pc for High Pressure Ball Valve |

| Nameplate | According to customer for High Pressure Ball Valve |

| Color | According to customer for High Pressure Ball Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |

For almost 10 years, RXVAL has continually committed itself to offer the best High Pressure Ball Valve products to meet a wide range of applications and requirements.

As an valve manufacturer, RXVAL has your perfect High Pressure Ball Valve solution. Our success in the valves industry is attributed to our customer-centric team of sales personnel, engineers, workers and after-service staff that are collectively committed to providing quality products at a price you would come to expect.