The globe valve and the gate valve have a certain similarity in appearance, and as both valves have the role of cutting off in the pipeline, Let's see what the difference is between the globe valve and the gate valve?

1. working principles

Whenever the globe valve opens and closed, the valve stem is lifted, i.e., as the handwheel is rotated, the hand-wheel rotates and lifts along with the valve stem. The gate valve rotates the hand-wheel to allow the valve stem to go up and down, and the position of the handwheel does not alter.

The gate valve only has two states that are completely open or completely shut. The opening and closing strokes of the gate is quite wide and the opening and closing time is very long;

Globe valves are generally used to stop, start, and regulate flow within a pipe. They’re made with a spherical body and a disc. The disc within the globe valve is designed to move up and down from the seat. These vertical movements allow the space between the disc and the seat to change slowly when the valve starts to close. This gives the valve good throttling ability and allows it to regulate flow within a pipeline.

2. Performance

The globe valve could be used for cutting and adjusting the flow. The fluid resistance of the globe valve is relatively high, and it is more difficult to open and shut, however since the gap between the valve plate and the sealing surface is small, the opening and closing stroke are small.

The gate valve could only be completely opened and closed. Once completely opened, the flow resistance of the fluid in the valve body path is almost zero, so the opening and closure of the gate valve would be very labour-saving, but the gate is far distant from the sealing surface so, the opening and closing time are large.

3. Installation

In both directions, the function of the gate valve is the same. The inlet and outlet directions for installation are not necessary, and the medium could flow in both directions.

The globe valve must be installed in full compliance with the position suggested by the arrow on the body of the valve.

4. Structure

The structure of the gate valve would be more complex than the globe valve. From the design point of view, the gate valve is taller than the globe valve, and theglobe valve is longer than the gate valve.

Globe valves are also designed with a stem connected to the bonnet right above the disc to maintain a tight seal when the valve is fully closed. Because of that, globe valves are less likely to experience seat leakage compared to other valves.

5.Applications

The gate valve is suitable for applications where low-pressure drops are of utmost importance. It’s a multidirectional valve. The globe valve is best used in applications where massive changes in pressure are not an issue. This valve is unidirectional.

6.Function

The gate valve is not designed for flow control; it is for isolation of media. The gate valve cannot handle the strength of the media flowing in a partially opened position. On the other hand, the globe valve is more of a control valve.

7.Service Life

Usually, the globe valve has better sealing performance and longer service life than the gate valve. And it is more expensive than a similar-sized gate valve, but the extra cost is worth it in the case when throttling is required.

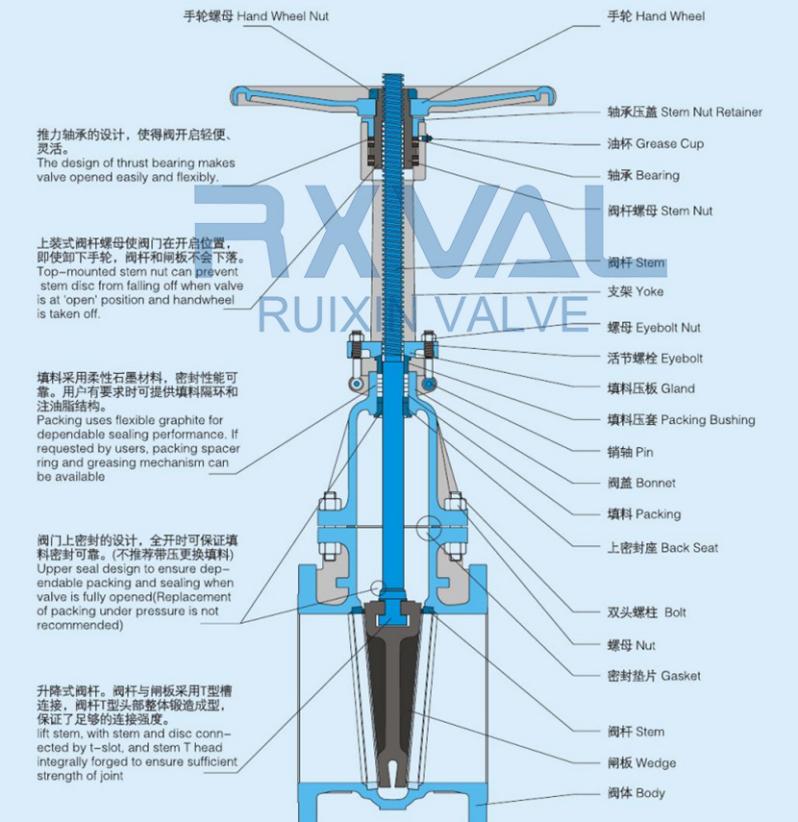

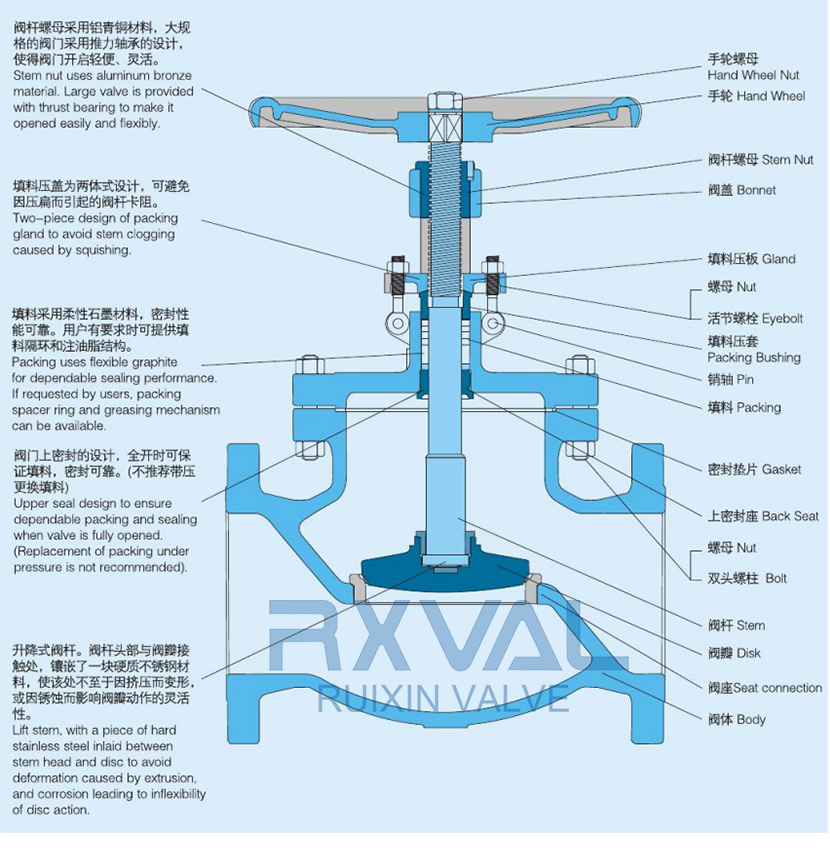

Please check below pictures for the difference between gate valve and globe valve by RXVAL.

Gate Valve Structure

Globe Valve Structure

FLANGE END FORGED STEEL GLOBE VALVE

●Outside Screw and Yoke (OS&Y)

●Bolted Bonnet

●Integral Backseat

●Welded Bonnet or Pressure Seated for high pressure

●Solid Wedge

●Leak Proof Body-Bonnet Joint with Spiral Wound Gasket

●Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

TRUNNION MOUNTED BALL VALVE WITH PNEUMATIC ACTUATOR

●Three Piece

●Full or Reduce Bore

●High Performance Sealing Mechanism

●Fire Safety Design

●Anti-Static Spring Device

●Blow-out proof stem

●Low Emission Design

●Double Block and Bleed function

●Locking Device for Lever Operation

●Low Operation Torque

●Self-relief of Excessive Cavity Pressure

●Zero Leakage

●Working for high temperature up to 540℃

F51 FORGED STEEL HIGH PRESSURE BALL VALVE WITH FLANGE END

●Three Piece

●Full or Reduce Bore

●High Performance Sealing Mechanism

●Fire Safety Design

●Anti-Static Spring Device

●Blow-out proof stem

●Low Emission Design

●Double Block and Bleed function

●Locking Device for Lever Operation

●Low Operation Torque

●Self-relief of Excessive Cavity Pressure

●Zero Leakage

●Working for high temperature up to 540℃

Post time: Jul-30-2022