What the design of Triple Offset Butterfly Valve ?

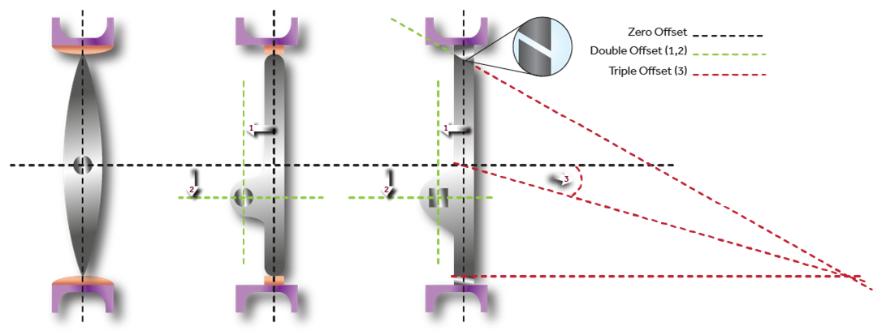

With the triple offset butterfly valve there are three offsets. Two are placed in a similar position to the double offset butterfly valve, while the third offset is the geometry of the seating surface, creating a type of cone shape of the disc and seat. This cone angle, along with the two eccentric shaft offsets, allows the disc to seal against the seat with no friction.Please check below pictures :

What the benefits of Triple Offset Butterfly Valve ?

The Triple Offset Butterfly Valve come in various designs and materials specific to the systems involved. They are recognized for excellent flow and control characteristics, tight sealing capabilities, and dependability across critical and severe applications. They are suited for applications requiring absolute zero leakage. Triple offset valves are hard facing, metal-to-metal valves with a longer lifespan. They are used in similar industries where a double offset valve would be used but are even more effective in demanding and tight applications such with over 900-1,500 psi or high-temperature gas or liquid.

Compare the Triple Offset Butterfly Valve and Normal Butterfly Valve

|

No |

Normal Butterfly valve | Triple offset butterfly valve |

|

01 |

This can't perform in high temperature and pressure environment |

This can perform efficiently in high temperature and pressure environment |

|

02 |

This type of valve has softer material of sealing arrangement | TOBVs have metal to metal sealing arrangement |

|

03 |

There is friction between valve seat to valve disc | No friction at all between valve disc and valve seat |

|

04 |

Low performing sealing action | High performing sealing action |

|

05 |

can't be used in vacuum piping system | works well in vacuum piping system |

|

06 |

Respectively Short life expectancy | Respectively long life expectancy |

|

07 |

Time to time maintenance required | Very less maintenance is required |

|

08 |

Cam action not available with non-offset valves | Offset in stem design provides cam action to life disc immediately from seat |

|

09 |

cavity and clogging | No cavity or clogging |

Conclusion

Triple Offset Butterfly Valve are much efficient and durable in high pressure and temperature condition with many effective sealing features. Its offset design and technology make it long-lasting with low maintenance.

FLANGE END FORGED STEEL GLOBE VALVE

●Outside Screw and Yoke (OS&Y)

●Bolted Bonnet

●Integral Backseat

●Welded Bonnet or Pressure Seated for high pressure

●Solid Wedge

●Leak Proof Body-Bonnet Joint with Spiral Wound Gasket

●Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

FLANGE FORGED STEEL CHECK VALVE

● Bolted Bonnet &Welded Bonnet

● Low Fugitive Emission

● Horizontal Type

● Valves with Low Cv Values

● Compact and Sturdy designs for high pressure-Temperature Service .

● A spring can be added to the lift type check valve as a piston type one.

● Swing Type Disc or Lift Type Disc

FORGED STEEL BALL VALVE WITH EXTENDED NIPPLE

●Fire Safety Seat Sealing

●Two-Piece or Three-Piece Forged Body with extended nipples

●Blowout-Proof Stem

●Anti-Static Spring Device

●100% leakage tested

●Extended Body is for option

F51 FORGED STEEL HIGH PRESSURE BALL VALVE WITH FLANGE END

●Three Piece

●Full or Reduce Bore

●High Performance Sealing Mechanism

●Fire Safety Design

●Anti-Static Spring Device

●Blow-out proof stem

●Low Emission Design

●Double Block and Bleed function

●Locking Device for Lever Operation

●Low Operation Torque

●Self-relief of Excessive Cavity Pressure

●Zero Leakage

●Working for high temperature up to 540℃

Post time: Jun-28-2022