Preparation before installation:

1. Ensure that the pipeline at the installation position of the ball valve is in the coaxial position, and the two flanges on the pipeline should be kept parallel to confirm that the pipeline can bear the weight of the ball valve itself. If it is found that the pipeline cannot bear the weight of the ball valve, provide corresponding support for the pipeline before installation.

2. To confirm whether there are impurities, welding slag, etc. in the pipeline, the pipeline must be cleaned.

3. Check the nameplate of the ball valve, and perform full-opening and full-closing operations on the ball valve several times to confirm that the valve can work normally, and then comprehensively check the details of the valve to ensure that the valve is intact.

4. Remove the protective cover at both ends of the valve, check whether the valve body is clean, and clean the valve body cavity. Since the sealing surface of the ball valve is spherical, even small debris may cause damage to the sealing surface.

Notes on installation:

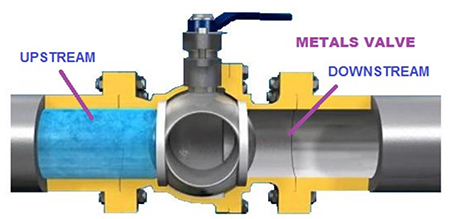

1. Any section of the ball valve can be installed at the upstream end, and the handle ball valve can be installed at any position in the pipeline. If a ball valve with an actuator (such as a gear box, electrical-pneumatic actuator) is configured, it must be installed vertically, at the inlet and outlet of the valve. in a horizontal position.

2. A gasket is installed between the ball valve flange and the pipeline flange according to the pipeline design requirements.

3. The bolts on the flange should be tightened symmetrically, sequentially and evenly.

4. If the ball valve work with pneumatic, electric and other actuators, complete the installation of the air source and power supply according to the instructions.

Post time: Jun-21-2022